Shop Here

Shop Here

So your generator is having some problems. Don’t worry: we are going to get through this together. Just breathe easy, and follow these simple instructions to help diagnose your unit’s problems.

Check the oil level in the crankcase. Add oil if the level is low. Keep in mind that attempting to run the generator on an uneven surface might cause the low-oil sensor to trigger despite there being enough oil.

Check the gas tank to make sure a sufficient amount of gasoline remains in the tank. Add fresh gasoline when necessary (to avoid clogs and hard starts, do not use old or stale gasoline. If the gasoline is older than two months, replace it with fresh gasoline).

The choke of any engine should be set to “closed” during startups and then moved to “open” once the engine warms up. Depending on the style of your generator, this choke lever may be positioned in a few different places. On many generators, it can be found directly above the air filter on the side of the unit. On others, the choke is builtin to the power control knob (such as with the WEN Inverter series). Either way, it should be set to closed (also referred to as the start or the choke position) when starting the generator. Once the engine ignites, move the choke to the ON/RUN/OPEN position for operation. If the engine is already warm (for instance, if it was running for a while and you are refueling), the choke lever should be set to the RUN (open) position for starting.

If the gas tank is full, but no fuel is getting to the carburetor, there may be a problem with the fuel line or fuel valve. The fuel valve controls the flow of fuel from the gas tank to the carburetor. Make sure that this is set to OPEN to allow fuel to flow into the proper channels. If the valve is set to OPEN but the fuel still does not properly flow, you can do two things. First of all, if there is a vacuum relief valve on top of the gas tank, make sure that it has been opened. Secondly, unplug the outlet hose from the intake side of the fuel valve to see if gasoline is freely flowing or not (have a bucket ready in case the gas flows fine). This will help you determine what part of the fuel line (if any) is clogged up. If there is an in-line fuel filter between the fuel valve and carburetor, also check it to make sure it is not blocked.

If you stored your generator for a long period of time without first draining the carburetor, the odds are high that it may be clogged by old gasoline. To fix this, shut off the fuel valve, and then open the carburetor drain found at the bottom of the carburetor’s bowl. If this still doesn’t work, you can remove the entire bowl from the bottom of the carburetor and clean out any stale fuel. Clean out the main jet (the brass nozzle found in the central stem) with a needle. To avoid this in the future, try to run your generator at least once a month, and never store it for long periods of time without draining the gas tank and the carburetor first. For a video guide on changing your generator’s carburetor, click here.

Overtime, deposits and buildup can appear on the spark plug. To check this, use the spark plug wrench included with your WEN generator to remove the spark plug and check for deposits. Clean the spark plug using a small knife or a similar tool as needed. Make sure the electrode is properly gapped (check the specifications page of your manual to see the proper gap for your particular model). To test the plug, pull the recoil starter while holding the spark plug’s body to the engine crankcase. If the sparks are strong with a blue color, then the ignition coil is good. If there is no spark or if the spark appears weak, remove the spark plug and cap. Put the end of the spark plug wire near the engine’s body and pull the recoil starter to check the ignition coil. If there are now sparks appearing between the spark plug boot and engine, then the spark plug needs to be replaced. If there are no sparks, the ignition coil may need to be replaced.

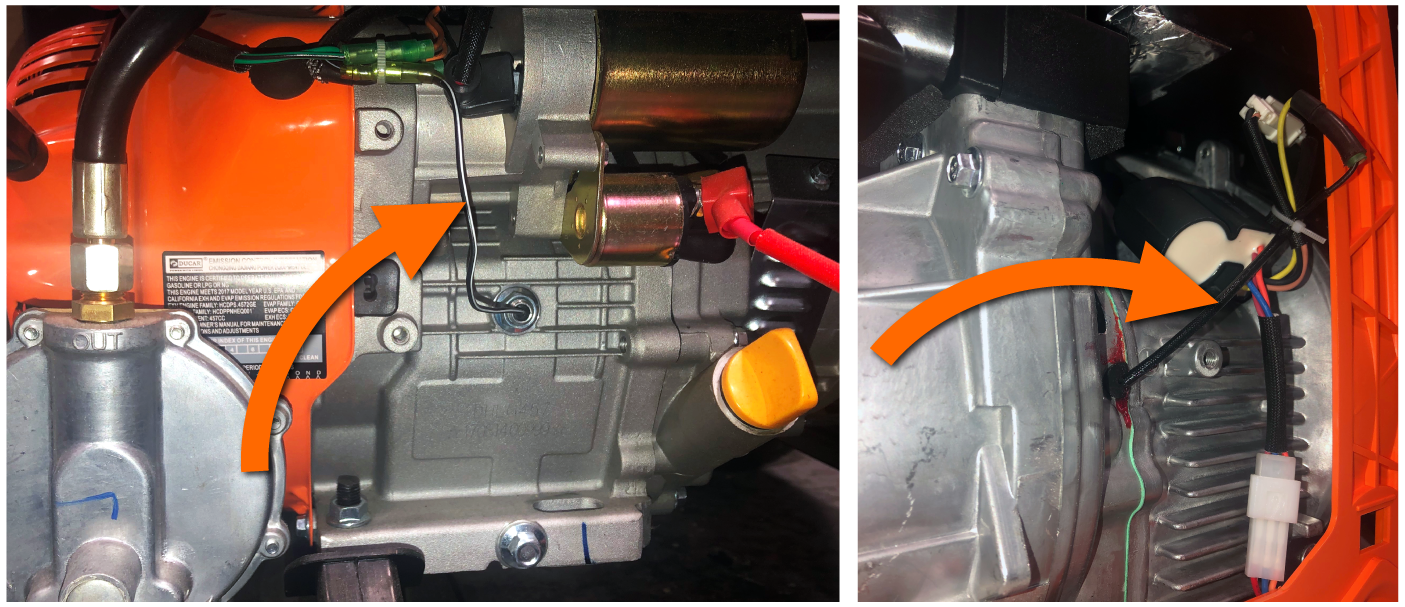

If the spark plug is properly gapped, deposit-free, and still not igniting, it may be that the low-oil sensor isn’t working correctly. To check this, disconnect the wire coming from the side of the crankcase - usually, it's a black, yellow, or black-and-yellow wire; see the images below. The location of this wire will vary slightly from generator to generator. If the generator starts once this has been unplugged, then the oil sensor is not working. Many times, running the engine with this unplugged for several minutes before reconnecting the oil sensor wire will resolve the problem. Otherwise, the engine may require a complete tear-down in order to replace the oil sensor. Also check out our helpful video on how to disconnect your oil sensor.

For electric start generators, the battery may lose its charge over time due to a lack of use. If this happens, simply start the generator using the pull starter to add juice back into the battery. If a recoil starter is unavailable on the unit, you may need to try alternative methods, such as a third-party battery charger.

Always make sure all electrical devices have been unplugged before starting the generator. You should never have anything plugged into the generator during startups, including vacant extension cords.

The air filter may need to be cleaned or replaced to let the necessary amount of air into the carburetor for ignition. Open up the air filter housing on the side of the generator and check the spongy air filter element inside. Clean or replace as needed. For video instructions on checking and changing a generator’s air filter, click here, or check out our handy video on replacing the air filter assembly.

Keep in mind, this is a general overview for generators of all shapes, styles and sizes. For a more specific breakdown of recommended starting and troubleshooting guidelines, refer to the manual of your specific model of generator. After all this, if you are still having trouble getting your generator started, feel free to give us a call at 1-847-429-9263 (M-F 8AM to 5PM CST) or drop us a message here to talk to our friendly and knowledgeable technical support team.

Comments

Leave a comment